Choosing the Right Kessler Spindle Repair Path for Milling Applications

Kessler spindles are widely used in high-end CNC milling environments where accuracy, rigidity, and thermal stability directly affect part quality. When performance begins to change, failures rarely present as sudden breakdowns. Instead, users see application-specific symptoms that depend on spindle size, speed range, and cutting load.

This guide helps answer a common question:

“Which Kessler spindle issue best matches what I’m seeing on my milling machine?”

Rather than listing specifications, this comparison focuses on how different Kessler spindle families behave as wear develops.

Common Kessler Milling Problems — Compared by Symptom

| Symptom You’re Seeing | Kessler Models Most Often Affected | What It Usually Indicates |

|---|---|---|

| Finish degrades at high RPM | C 40 | Bearing wear or balance sensitivity at speed |

| Vibration only in certain speed ranges | C 40 | Dynamic imbalance amplified by high RPM |

| Accuracy drifts as spindle warms | DMS 80 | Thermal growth and preload shift |

| Parts start in tolerance, drift later | DMS 80 / DMS 100 | Heat-related bearing behavior |

| Instability during heavy cuts | DMS 100 | Loss of stiffness under sustained load |

| Process window keeps shrinking | DMS 80 / DMS 100 | Progressive internal wear masked by parameter changes |

These patterns reflect real milling behavior, not theoretical limits.

C-Series vs DMS-Series: What’s the Real Difference?

C-Series (e.g., C 40)

Best suited for:

- High-speed precision milling

- Finishing and semi-finishing

- Mold, die, medical, and aerospace work

- Applications where balance and tool interface stability matter most

How wear shows up:

- Finish breaks down at higher RPM

- Vibration appears only in specific speed bands

- Reducing RPM temporarily improves results

DMS-Series (e.g., DMS 80, DMS 100)

Best suited for:

- Heavy milling and sustained cutting

- Larger cutters and higher material removal

- Longer cycle times under load

- Applications where rigidity and thermal mass matter most

How wear shows up:

- Accuracy drifts as temperature rises

- Stability decreases during longer or heavier cuts

- Operators reduce parameters to maintain results

Which Kessler Spindle Problem Sounds Like Yours?

“The spindle is quiet, but finish falls apart at high speed.”

This is most often associated with Kessler C 40 spindles, where small balance or bearing changes become noticeable as RPM increases.

“Parts are accurate at startup but drift during longer runs.”

When accuracy changes correlate with heat and time, Kessler DMS 80 spindles are commonly involved.

“Light cuts are fine, but heavy milling causes instability.”

This pattern strongly aligns with Kessler DMS 100, where internal stiffness loss shows up under sustained cutting load.

“We keep backing off parameters to keep parts in spec.”

Repeated compensation usually indicates internal spindle wear, not tooling or CAM issues.

Why Kessler Milling Spindles Fail the Way They Do

Kessler spindles are engineered for precision, but different designs prioritize different strengths:

- C-series: speed, balance, responsiveness

- DMS-series: rigidity, thermal mass, sustained load

As a result:

- C-series spindles reveal problems at RPM

- DMS-series spindles reveal problems under heat and load

Waiting for noise or alarms is often too late in precision milling.

Repair vs “Working Around the Problem”

One of the most expensive mistakes in milling environments is tuning around spindle wear:

- Permanently lowering RPM

- Reducing depth of cut

- Avoiding certain tools

- Increasing inspection and rework

These steps may stabilize output temporarily, but they don’t restore balance, preload, or stiffness.

In many cases, early spindle evaluation keeps repairs limited and avoids unnecessary replacement.

Manufacturer Guidance for Kessler Spindles

According to Kessler documentation and service guidance, maintaining milling performance depends on:

- Proper warm-up before precision or heavy milling

- Avoiding sustained operation beyond intended load

- Monitoring accuracy and finish trends over time

- Maintaining clean cooling and lubrication systems

- Investigating changes early rather than compensating indefinitely

Users should always consult official Kessler documentation specific to their spindle model and configuration.

How This Comparison Hub Is Meant to Be Used

This page is designed to:

- Help identify which Kessler spindle behavior matches your symptoms

- Direct you to the appropriate model-specific page

- Reduce guesswork before scrap, downtime, or repair scope increases

Each individual model page goes deeper into symptoms, failure modes, repair options, and preventative practices.

Final Thought

Kessler spindles rarely fail suddenly.

They signal problems through changes in finish, accuracy, thermal behavior, or load response first. Recognizing which signal you’re seeing is the fastest way to decide when repair makes sense.

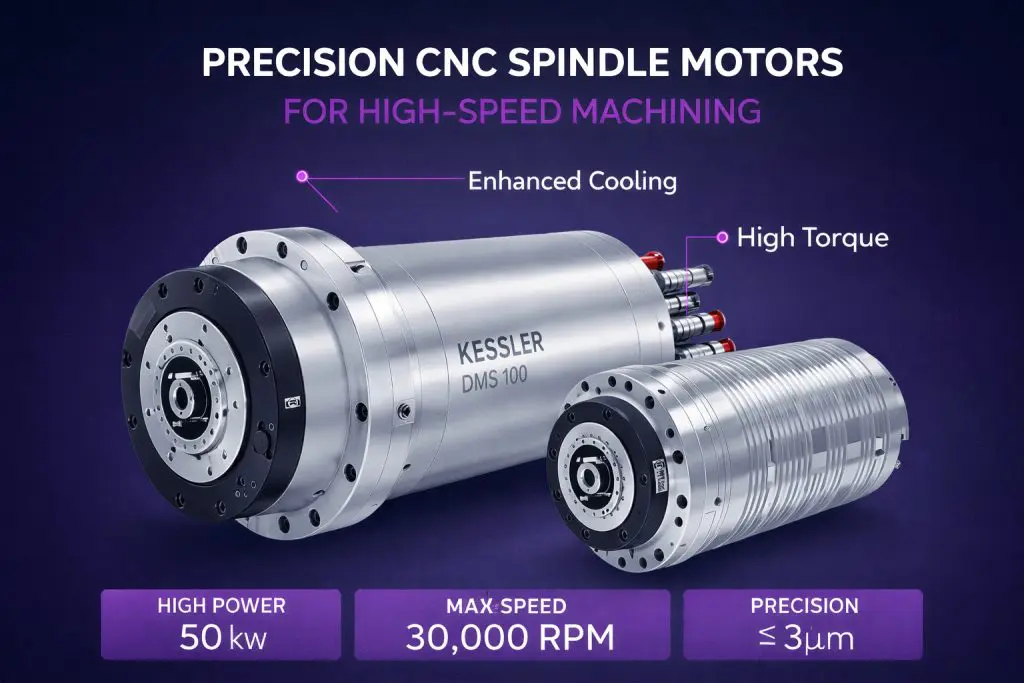

Illustrations are representative and used for educational purposes; actual spindle configurations may vary.