What Levels of Repair Exist — and What Type of Bearings Are Used?

Bearing replacement is one of the most common services performed during CNC spindle repair. However, not all bearing replacements are equal. The level of service, preload control, balance procedures, and bearing type selection dramatically affect long-term performance.

This guide explains:

- The different levels of spindle bearing replacement

- The types of bearings used in CNC spindles

- When bearing replacement alone is appropriate

- When full rebuild is required

Why Bearing Replacement Matters

Spindle bearings determine:

- Runout accuracy

- Surface finish quality

- Thermal stability

- RPM capability

- Tool life

As bearings wear, the first symptoms are often:

- Finish degradation

- Speed-specific instability

- Heat buildup

- Shrinking stable RPM ranges

Catching bearing wear early can prevent secondary shaft or housing damage.

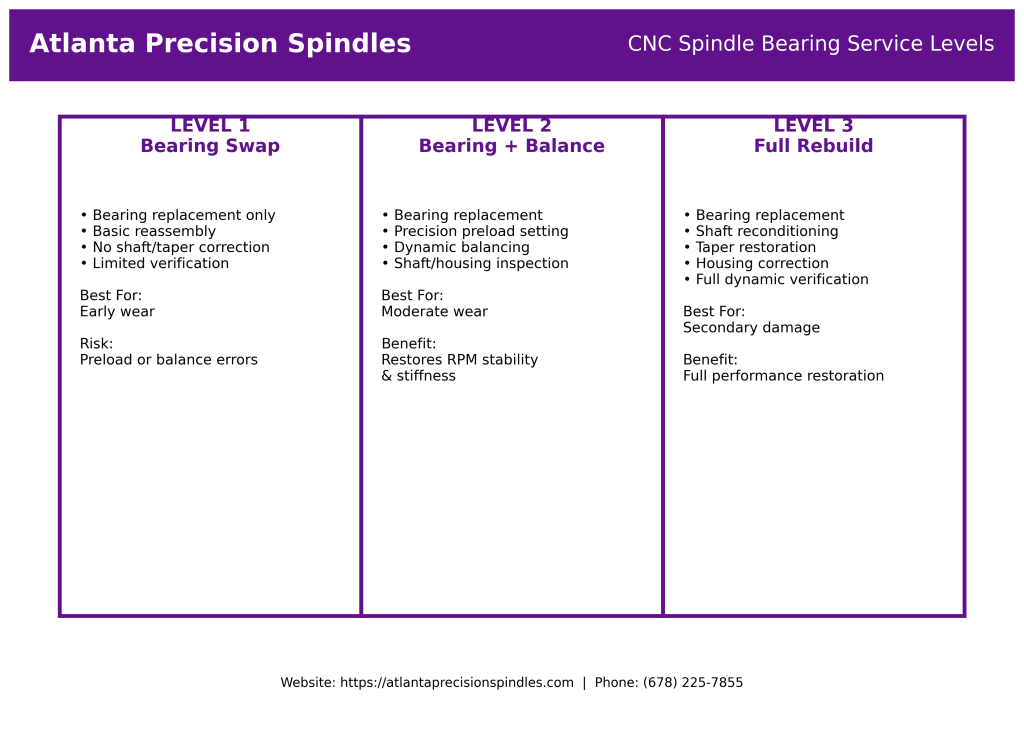

Levels of Spindle Bearing Replacement

Not all bearing jobs are the same. There are generally three levels of service.

Level 1: Bearing Swap (Minimal Service)

What it includes:

- Removal and replacement of worn bearings

- Basic reassembly

- No major shaft or housing correction

When it may be appropriate:

- Early wear

- No shaft damage

- No taper issues

- No thermal drift beyond bearing wear

Risks if not done precisely:

- Incorrect preload

- Imbalance

- Reduced service life

This level is typically suitable only when no secondary damage has occurred.

Level 2: Bearing Replacement + Balance & Preload Reset

What it includes:

- Bearing replacement

- Precision preload setting

- Dynamic balancing

- Inspection of shaft and housing

- Minor correction of wear surfaces

This is the most common professional service level.

It restores:

- Proper preload

- Stability across RPM range

- Thermal consistency

This level is appropriate when wear has progressed but not damaged major structural components.

Level 3: Full Spindle Rebuild (Beyond Bearings)

What it includes:

- Bearing replacement

- Shaft journal inspection and reconditioning

- Taper restoration (if needed)

- Housing correction

- Full dynamic balancing

- Complete performance verification

This is necessary when:

- Shaft scoring exists

- Preload instability caused internal damage

- Contamination caused surface wear

- Taper damage affects tool seating

Waiting too long can move a Level 2 repair into Level 3 territory.

Types of Bearings Used in CNC Spindles

Spindle applications determine bearing type selection. The most common are:

Angular Contact Ball Bearings

Most common in:

- Milling spindles

- Router spindles

- High-speed applications

Advantages:

- High precision

- Good axial and radial load handling

- Suitable for high RPM

These are often arranged in matched sets with specific preload configurations.

Hybrid Ceramic Bearings

Common in:

- High-speed milling

- High-RPM finishing

- Precision 5-axis applications

Advantages:

- Reduced heat generation

- Higher RPM capability

- Lower friction

- Improved longevity

Often used in upgrades where speed and thermal stability matter.

Cylindrical Roller Bearings

Common in:

- Heavy steel milling

- High-torque spindles

Advantages:

- High radial load capacity

- Increased stiffness

Typically paired with angular contact bearings for axial support.

Duplex, Triplex & Quad Bearing Sets

Spindles frequently use:

- Matched pairs (Duplex)

- Triple stacks (Triplex)

- Quad sets for high stiffness

Correct orientation and preload are critical. Even minor assembly errors can cause instability.

Bearing Preload — Why It’s Critical

Preload determines:

- Stiffness

- Heat generation

- RPM stability

- Bearing life

Too tight:

- Excessive heat

- Reduced bearing life

Too loose:

- Vibration

- Poor finish

- Tool wear

Professional preload setting uses precision measurement tools and controlled assembly methods.

When Is Bearing Replacement Enough?

Bearing replacement alone is often sufficient when:

- Finish degradation is gradual

- Heat increases moderately

- No shaft damage is present

- No taper wear is visible

If the spindle has run with severe vibration or contamination, additional work may be required.

Signs That Bearings Are Not the Only Issue

- Taper fretting or tool seating problems

- Significant shaft scoring

- Persistent instability after speed changes

- Excessive heat even after bearing replacement

These indicate a deeper rebuild may be necessary.

Preventative Strategy

Monitoring these trends can keep repairs at Level 1 or Level 2:

- Finish quality logs

- Tool life tracking

- Thermal trend monitoring

- Speed-range stability

Early intervention prevents escalation.

Final Thought

Not all spindle bearing replacements are equal.

Understanding the level of service and the type of bearings used helps ensure that performance is restored — not just temporarily improved.

Precision preload control, dynamic balancing, and correct bearing selection are what separate short-term fixes from long-term stability.