How Finish Quality, Thermal Stability, and Load Reveal Spindle Condition

Grinding spindles operate under continuous contact, sustained radial load, and extremely tight surface-finish requirements. Unlike milling or routing spindles, grinding spindles rarely show dramatic vibration or noise early on.

Instead, finish degradation, heat buildup, and process inconsistency are usually the first indicators of spindle wear.

What Grinding Demands From a Spindle

Grinding applications typically involve:

- Continuous wheel contact

- High radial loading

- Long duty cycles

- Finish tolerances measured in microns

Because of this, grinding spindles prioritize:

- Bearing stiffness and preload stability

- Thermal consistency

- Low vibration under continuous load

- Excellent balance at operating speed

Speed matters — but stability matters more.

Spindle Designs Commonly Used for Grinding

Most grinding machines rely on:

- Belt-driven spindles for torque stability and serviceability

- High-precision direct-drive spindles for fine finishing

- Designs optimized for continuous load, not intermittent cutting

Grinding spindles are engineered to run smoothly for long periods, which is why wear often progresses quietly.

🔗 Grinding Spindles — Common Manufacturers & Models

Below are manufacturers and specific spindle lines most commonly encountered in cylindrical, ID, and surface grinding environments, along with clear internal-link targets.

Omlat — BELT-G Grinding Spindles

Omlat BELT-G spindles are widely used in cylindrical and internal grinding applications where torque stability and thermal behavior are critical.

Common grinding models

- OM-BELT 180 G

- OM-BELT 200 G

- OM-BELT 240 G

- OM-BELT 260 G

Typical grinding symptoms

- Finish quality slowly degrading

- Wheel marks appearing under load

- Heat buildup during long cycles

IBAG — Precision Grinding Spindles

IBAG spindles are commonly used in high-precision internal and cylindrical grinding applications.

Common grinding models

- IBAG HF series

- IBAG internal grinding spindles

Typical grinding symptoms

- Finish inconsistency before vibration

- Thermal drift affecting size control

NSK — Grinding & Precision Spindles

NSK spindles are frequently used in precision grinding where bearing quality and preload control are critical.

Common grinding applications

- Surface grinding

- ID grinding

- Precision finishing

Typical grinding symptoms

- Size variation during long runs

- Increased heat at steady load

GMN — High-Speed Grinding Spindles

GMN spindles are used in high-speed grinding and finishing applications where balance and thermal behavior are tightly controlled.

Common grinding lines

- GMN high-speed grinding spindles

- Precision finishing spindles

Typical grinding symptoms

- Speed-specific finish issues

- Sensitivity to balance changes

Fischer — Fine Grinding & Micro-Finishing

Fischer spindles are often used in ultra-precision grinding and micro-finishing environments.

Common grinding applications

- Fine surface grinding

- Micro-precision finishing

Typical grinding symptoms

- Finish breakdown before audible issues

- Thermal sensitivity during long cycles

Early Warning Signs in Grinding Spindles

Finish degradation before vibration

A classic grinding indicator:

- Surface roughness increases

- Spark-out becomes inconsistent

- Wheel dressing frequency increases

This often points to bearing wear or preload change, not wheel condition alone.

Heat buildup during continuous operation

Grinding spindles may show:

- Housing temperature rising steadily

- Dimensional drift over long cycles

Heat is frequently caused by internal friction, not coolant issues.

Increasing sensitivity to wheel balance

As spindles wear:

- Previously acceptable wheels become unstable

- Dressing no longer restores finish

This is often an early sign of reduced spindle stiffness.

Why Grinding Spindle Problems Are Often Misdiagnosed

Grinding issues are commonly blamed on:

- Wheel selection

- Dressing parameters

- Coolant delivery

While those matter, spindle condition is often the underlying contributor, especially when finish and thermal symptoms appear together.

Repair vs Replacement for Grinding Spindles

Replacement

Replacement may be necessary after severe damage but often involves:

- Long lead times

- High cost

- Machine downtime

Professional Spindle Repair

When addressed early, repair can:

- Restore finish quality

- Improve thermal stability

- Extend spindle service life

- Reduce scrap

DIY Risks in Grinding Applications

Grinding spindles are especially sensitive to:

- Bearing preload errors

- Balance issues

- Assembly cleanliness

DIY internal work often increases finish problems rather than fixing them.

Is It the Spindle—or the Machine?

Grinding issues are often spindle-related when:

- Finish changes without machine alarms

- Heat localizes at the spindle housing

- Problems worsen over long runs

Machine geometry issues usually appear immediately and consistently.

- Is It the Spindle or the Machine? Diagnostic Guide

Final Thought

Grinding spindles rarely announce failure.

They communicate wear through finish changes, heat, and stability loss long before vibration or downtime occurs. Recognizing those signals early is the key to protecting quality and throughput.

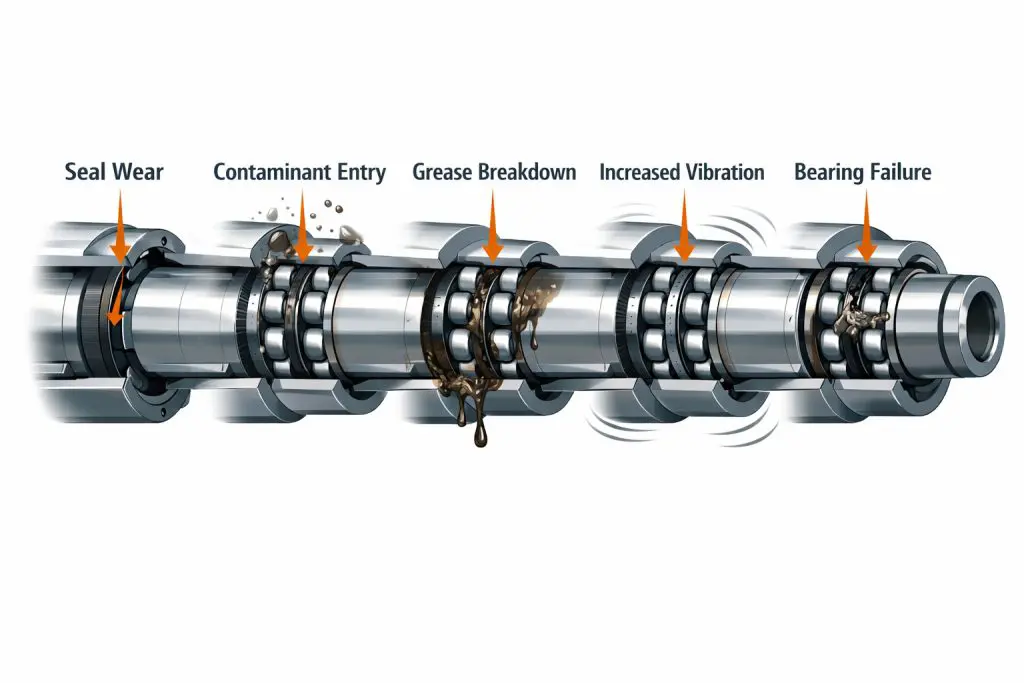

Illustrations are representative and used for educational purposes; actual spindle configurations may vary.