Kessler DMS 80 Spindle Repair: Milling Accuracy Under Heat and Load

The Kessler DMS 80 is engineered for high-precision milling applications where thermal stability, rigidity, and tool interface integrity directly affect part accuracy. When internal conditions begin to change, performance rarely degrades all at once. Instead, users notice gradual shifts—milling accuracy drifting as the spindle warms, stiffness decreasing during heavier cuts, or a narrowing stable process window—while the spindle itself continues to sound normal. These patterns often indicate bearing preload or thermal-growth changes inside the spindle rather than tooling or programming issues.

How the Kessler DMS 80 Is Used in Milling Applications

The DMS 80 is most commonly found in high-end CNC milling centers performing operations such as:

- Precision contour milling

- Pocketing and profiling with moderate-to-high cutting loads

- Mold, die, aerospace, and medical machining

- Applications using HSK tooling, where interface rigidity and repeatability are critical

In milling, the spindle is constantly exposed to interrupted cuts, side loads, and sustained torque, making internal stiffness and thermal behavior far more important than peak RPM alone.

Early Milling-Related Symptoms Seen in DMS 80 Spindles

Accuracy drift during longer milling cycles

Users often report:

- Parts starting in tolerance, then drifting as the spindle heats

- Increased need for compensation during long roughing or semi-finish passes

- Inconsistent results between cold starts and warm operation

Finish breakdown under cutting load

As internal wear progresses:

- Finish degrades more noticeably during side milling

- Tool marks become inconsistent

- Results improve temporarily when parameters are reduced

These symptoms frequently appear before vibration or noise becomes obvious.

What’s Typically Happening Inside the DMS 80 During Milling

Bearing preload changes under thermal and cutting stress

During milling:

- Sustained side loads increase bearing stress

- Heat buildup alters preload characteristics

- Shaft growth affects tool position and interface stability

As bearings wear, these effects intensify, making milling accuracy increasingly sensitive to temperature and load.

Why Milling Issues Are Often Misdiagnosed

Initial troubleshooting usually targets:

- Cutting strategies or step-over

- Toolholders and cutters

- CAM parameters

While these factors matter, repeated accuracy and finish issues that correlate with heat and cutting force often point back to the spindle itself.

Repair Options for Kessler DMS 80 Milling Spindles

Milling-focused spindle evaluation

A proper evaluation can:

- Assess bearing preload under simulated milling loads

- Correlate thermal behavior with accuracy loss

- Identify internal wear before secondary damage occurs

Precision bearing rebuild and dynamic balancing

When wear is confirmed:

- Bearings are replaced to OEM-level specifications

- Preload and stiffness are restored

- Balance is verified for stable milling across the operating range

The result is improved accuracy, finish consistency, and process stability during milling operations.

Repair vs Replacement — Especially Critical for Milling Spindles

In milling applications, continuing to run a worn spindle can:

- Accelerate tool wear

- Increase scrap and rework

- Mask problems until repair scope expands

Because Kessler spindles represent a significant investment, early repair often preserves value and avoids unnecessary replacement.

Manufacturer-Recommended Maintenance for Kessler Milling Spindles

According to Kessler documentation and service guidance, maintaining milling performance depends on practices that support thermal stability and bearing life.

Manufacturer guidance generally emphasizes:

- Proper warm-up before precision milling

- Avoiding prolonged operation at excessive cutting loads

- Monitoring accuracy and finish trends over time

- Maintaining clean cooling and lubrication systems

- Investigating accuracy changes early rather than compensating indefinitely

Users should always consult official Kessler documentation specific to their spindle model and configuration for detailed guidance.

Preventative Practices That Help DMS 80 Milling Spindles Last Longer

To extend service life in milling applications:

- Track accuracy relative to spindle temperature

- Avoid permanently reducing cutting parameters to hide instability

- Address load- and heat-related changes early

In milling, heat and load reveal spindle problems long before failure occurs.

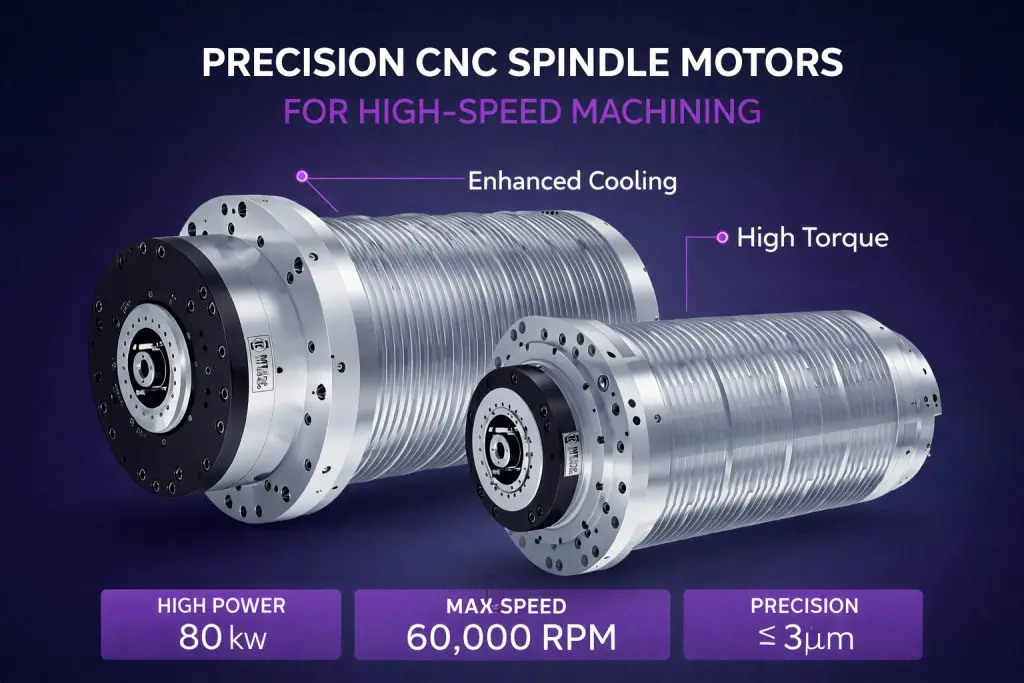

Illustrations are representative and used for educational purposes; actual spindle configurations may vary.