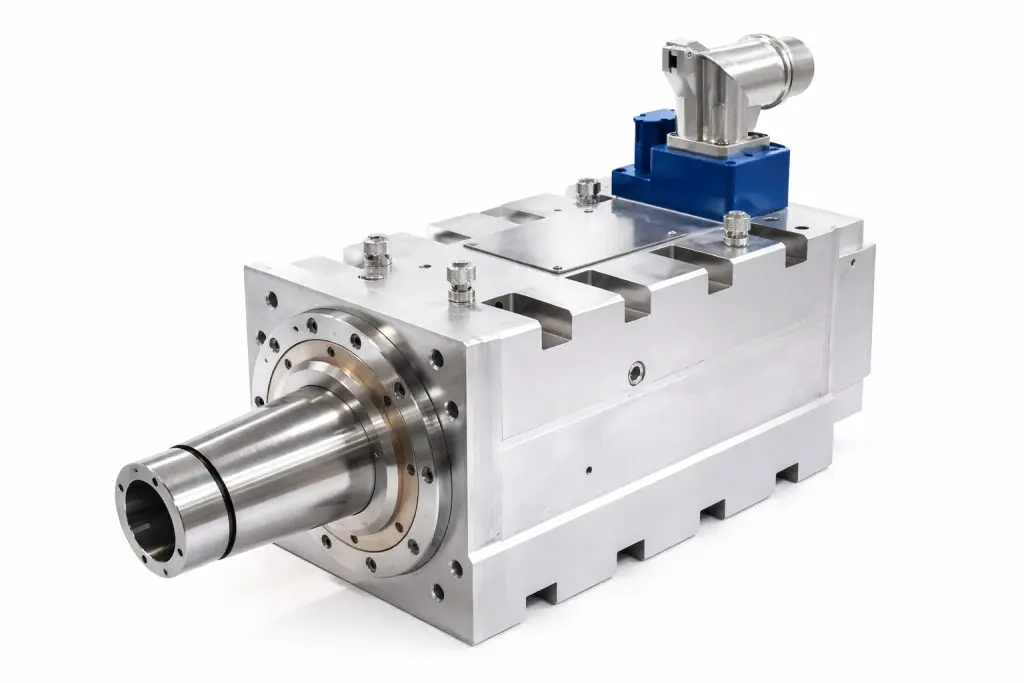

SCM Electrospindle Repair

Diagnosing Performance Issues in SCM CNC Electrospindles

SCM electrospindles are widely used across CNC routers, aluminum machining centers, and hybrid production machines where speed, automation, and surface finish are critical. When performance issues arise, these electrospindles rarely fail all at once. Instead, users experience gradual changes in cut quality, accuracy, or reliability that often go misdiagnosed.

This page serves as an overview of common SCM electrospindle problems, how they typically present, and when repair becomes the smarter option compared to continued operation or replacement.

What Makes SCM Electrospindles Different

Unlike mechanical spindles, SCM electrospindles integrate:

- High-speed motor sections

- Precision bearing assemblies

- Encoders and feedback systems

- Automated tool change (ATC) interfaces

This integration allows for excellent performance—but it also means that electrical, thermal, and mechanical issues often overlap, making diagnosis more complex.

Common Applications for SCM Electrospindles

SCM electrospindles are commonly found in:

- CNC routers for woodworking

- Aluminum machining and profiling

- Composite cutting and trimming

- High-speed finishing operations

- Machines using HSK or ISO tooling with ATC

Because these applications rely heavily on speed and automation, even small changes in spindle condition can affect throughput and part quality.

Common SCM Electrospindle Symptoms

Surface finish degradation

One of the earliest signs of electrospindle wear is:

- Finish quality declining despite unchanged tooling

- More sanding or secondary finishing required

- Visual inconsistency across parts

This often points to bearing wear or balance sensitivity, not programming issues.

Heat buildup during operation

Users may notice:

- Spindles running hotter than normal

- Thermal alarms appearing more frequently

- Performance changing as temperature rises

Heat buildup can be caused by bearing preload changes, lubrication issues, or motor inefficiency, and should not be ignored.

Vibration or noise at speed

Unlike mechanical spindles:

- Electrospindles may vibrate only at higher RPM

- Noise may be subtle rather than obvious

- Problems may disappear when speed is reduced

This behavior is commonly linked to bearing condition or dynamic balance, not the tool itself.

Tool change or encoder-related issues

Because SCM electrospindles often include ATC and feedback systems, users may also encounter:

- Inconsistent tool clamping

- Tool length measurement errors

- Encoder or positioning faults

These issues often coexist with mechanical wear rather than occurring independently.

Why SCM Electrospindle Issues Are Often Misdiagnosed

SCM electrospindle problems are frequently blamed on:

- Tooling or holders

- Feeds and speeds

- Electrical drives or controls

While these factors matter, electrospindle wear often affects multiple systems at once, making it easy to chase symptoms instead of the root cause.

Repair vs Replacement for SCM Electrospindles

SCM electrospindles represent a significant investment. When problems appear, users often face a decision:

- Continue operating with compensations

- Replace the electrospindle through the OEM

- Evaluate and repair the existing unit

In many cases, early repair restores performance and extends service life at a fraction of replacement cost, especially when issues are caught before secondary damage occurs.

What SCM Electrospindle Repair Typically Involves

Depending on condition, repair may include:

- Precision bearing replacement

- Dynamic balancing for high-speed operation

- Motor and electrical inspection

- Encoder and ATC interface verification

- Thermal and vibration testing

A comprehensive evaluation helps determine whether repair is viable and how extensive it needs to be.

Manufacturer Guidance for SCM Electrospindles

Manufacturer documentation for SCM machines emphasizes:

- Proper warm-up before high-speed operation

- Avoiding shock loads during engagement

- Maintaining clean cooling and lubrication systems

- Monitoring vibration, heat, and finish trends

- Investigating changes early rather than compensating indefinitely

Users should always consult official SCM documentation specific to their machine and spindle configuration for detailed guidance.

SCM electrospindles rarely fail without warning.

They communicate problems through heat, finish changes, vibration at speed, or automation inconsistencies first. Recognizing these signals early is the key to reducing downtime and avoiding unnecessary replacement.

Illustrations are representative and used for educational purposes; actual spindle configurations may vary.