Grinding Shops

Grinding Spindle Rebuild vs Replacement

A Cost & Value Comparison Guide When a grinding spindle begins to lose finish quality, develop vibration, or show thermal drift, one of the first questions is: Should we rebuild the spindle — or replace it? The answer depends on spindle condition, structural integrity, production urgency, and long-term cost strategy. This guide breaks down the…

Read MoreSpindles for Grinding

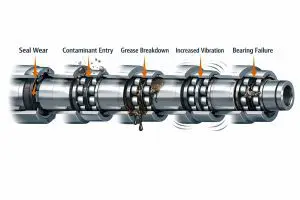

How Finish Quality, Thermal Stability, and Load Reveal Spindle Condition Grinding spindles operate under continuous contact, sustained radial load, and extremely tight surface-finish requirements. Unlike milling or routing spindles, grinding spindles rarely show dramatic vibration or noise early on. Instead, finish degradation, heat buildup, and process inconsistency are usually the first indicators of spindle wear.…

Read MoreSpindle Repair Services for Internal Grinding (ID) Shops

Internal grinding is one of the most demanding machining processes in manufacturing. Small wheel diameters, high spindle speeds, tight bore tolerances, and long cycle times leave zero tolerance for vibration, runout, or thermal instability. Atlanta Precision Spindles specializes in spindle repair and optimization for Internal Diameter (ID) grinding shops, where precision is measured in microns…

Read MoreSpindle Repair Services for Grinding Shops & Precision Grinding

Precision grinding leaves no room for vibration, heat fluctuation, or runout. Even small deviations can destroy surface finish, compromise tolerances, and dramatically reduce wheel and spindle life. Atlanta Precision Spindles specializes in spindle repair and optimization for grinding shops—where balance, thermal stability, and accuracy are critical to daily production. Why Grinding Applications Are Uniquely Demanding…

Read More