High-Speed Milling

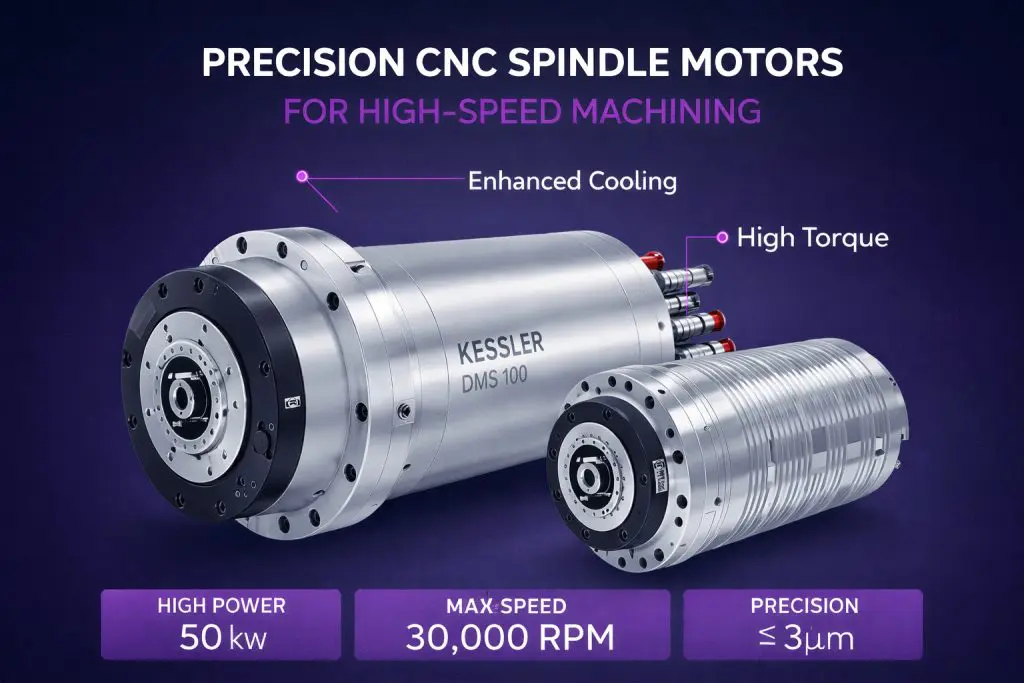

Spindles for High-Speed Milling

How Speed, Balance, and Thermal Stability Shape Performance—and Failure High-speed milling places very different demands on a spindle than general machining or heavy cutting. In these applications, spindle condition directly affects surface finish, tool life, and dimensional accuracy, often long before alarms or noise appear. This page explains how high-speed milling spindles behave, what early…

Read MoreKessler C 40 Spindle Repair: Precision Milling When Stability Starts to Shift

The Kessler C 40 is engineered for high-speed precision milling applications where tool interface stability, thermal control, and dynamic balance directly affect part quality. When internal conditions begin to change, performance rarely degrades suddenly. Instead, users notice subtle shifts—finish quality declining at higher RPM, accuracy changing as the spindle warms, or vibration appearing only in…

Read MoreIBAG HF120 Spindle Repair: When Accuracy Starts to Fade

The IBAG HF120 is designed for applications where accuracy and finish matter more than brute force. When performance begins to change, it rarely does so dramatically. Instead, users notice gradual shifts—subtle finish degradation, minor size variation, or reduced repeatability—while the spindle itself continues to run quietly. These early warning signs are often the result of…

Read MoreGMN UH Series Spindle Comparison Guide

Understanding UH Spindle Accuracy Issues by Model The GMN UH series is designed for ultra-precision grinding applications where roundness, form accuracy, and repeatability matter more than speed or power. Unlike production spindles that fail loudly, UH spindles typically degrade quietly—with accuracy drifting long before vibration or noise appears. This guide helps answer one key question:…

Read MoreGMN UH 100 Spindle Repair: When Size and Form Drift on Larger Bores

GMN UH 100 Spindle Repair: When Size and Form Drift on Larger Bores If you’re researching GMN UH 100 spindle repair, the spindle likely still runs quietly and smoothly. There’s no chatter, no obvious vibration — yet parts are no longer holding size or form, especially on larger internal diameters. This is a common UH…

Read MoreGMN UH 80 Spindle Repair: When Accuracy Slips Without Noise

If you’re researching GMN UH 80 spindle repair, the spindle likely hasn’t “failed” in an obvious way. It still runs quietly. There’s no chatter. Yet roundness, form, or repeatability are no longer what they used to be. For UH-series spindles, this is the most common failure pattern — accuracy degradation without audible warning. How the…

Read More