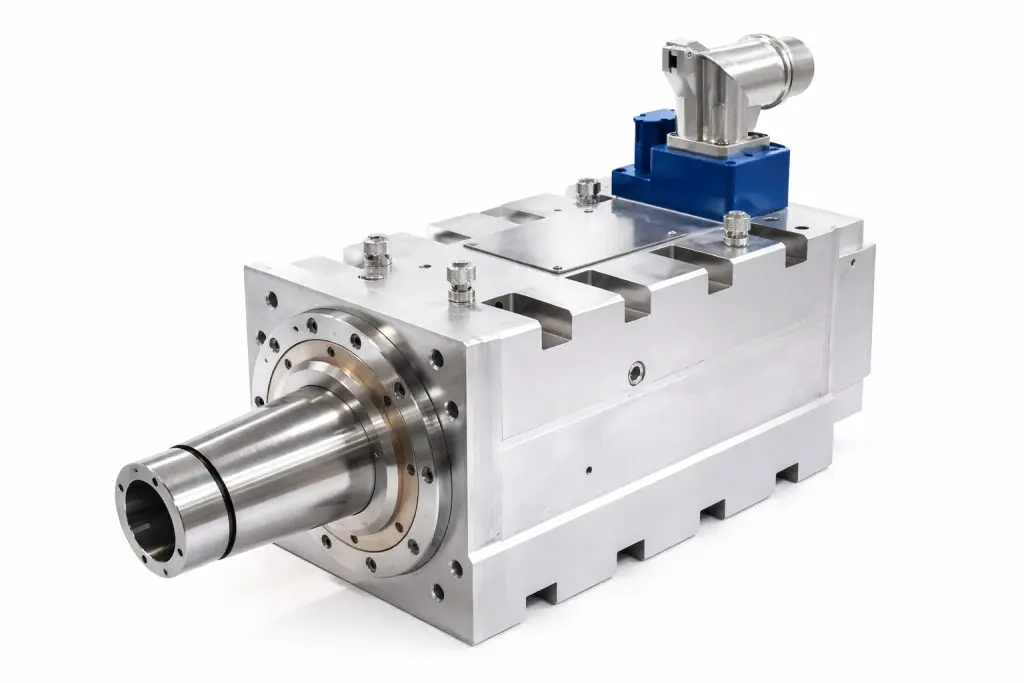

SCM Spindles

SCM Router Spindle Preventative Maintenance

How to Extend the Life of SCM CNC Router Electrospindles SCM CNC router spindles are built for high-speed production, frequent tool changes, and continuous operation. In these environments, spindle problems rarely appear as sudden failures. Instead, performance gradually drifts—cut quality changes, heat increases, or reliability becomes inconsistent. Preventative maintenance for SCM router spindles focuses on…

Read MoreSCM CNC Router Electrospindle Repair

When Cut Quality, Heat, or Reliability Starts to Slip SCM CNC router electrospindles are designed to deliver high-speed performance, automated tool changes, and consistent cut quality across demanding production environments. When problems develop, these electrospindles rarely fail all at once. Instead, users begin to notice gradual changes in finish, heat, vibration, or tool-change reliability that…

Read MoreSCM Electrospindle Repair

Diagnosing Performance Issues in SCM CNC Electrospindles SCM electrospindles are widely used across CNC routers, aluminum machining centers, and hybrid production machines where speed, automation, and surface finish are critical. When performance issues arise, these electrospindles rarely fail all at once. Instead, users experience gradual changes in cut quality, accuracy, or reliability that often go…

Read More