Spindle Maintenance

CNC Spindle Bearing Replacement

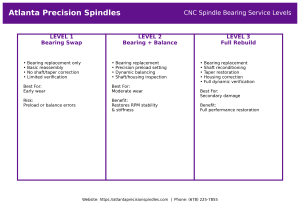

What Levels of Repair Exist — and What Type of Bearings Are Used? Bearing replacement is one of the most common services performed during CNC spindle repair. However, not all bearing replacements are equal. The level of service, preload control, balance procedures, and bearing type selection dramatically affect long-term performance. This guide explains: Why Bearing…

Read MoreSteel Milling Spindle Preventative Maintenance

Protect Torque Stability, Stiffness, and Thermal Control Under Load Steel milling spindles operate under sustained cutting forces, deep engagements, and long cycle times. Unlike high-speed finishing applications, steel machining exposes spindle wear through load-dependent chatter, shrinking process windows, and thermal drift. Preventative maintenance in steel milling is about identifying those load-related changes early — before…

Read More5-Axis Spindle Preventative Maintenance

Protect Accuracy, Surface Finish, and Multi-Orientation Stability 5-axis machining introduces stresses that traditional vertical or horizontal machines never see. As the head tilts and rotates, load direction, leverage, and thermal behavior constantly change. Because of this, spindle wear in 5-axis systems often appears only at certain angles or during complex toolpaths. Preventative maintenance in 5-axis…

Read MoreGrinding Spindle Preventative Maintenance

Grinding spindles operate under continuous radial load, long duty cycles, and tight surface finish tolerances. Unlike milling or routing spindles, grinding spindles rarely fail loudly. Instead, they gradually signal wear through finish degradation, heat buildup, size variation, and process instability. Preventative maintenance is about recognizing those early signals—before scrap, rework, or catastrophic damage occurs. Why…

Read MoreCNC Routing Spindle Preventative Maintenance

Stop Finish Problems and Tool-Life Loss Before the Spindle Fails CNC routing spindles often run long hours under constant side load. Because of that duty cycle, routing spindles rarely “fail all at once.” Instead, they typically show early warning signs through finish quality, edge condition, tool life, and heat—well before you hear obvious vibration. This…

Read More