Spindles for Steel Milling

Spindles for Steel Milling

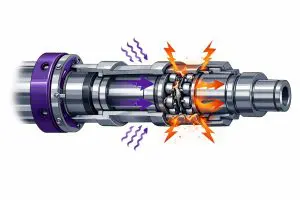

How Torque, Stiffness, and Thermal Control Drive Performance Steel milling places sustained mechanical and thermal demands on a spindle. Unlike high-speed finishing, steel cutting exposes weakness through load, stiffness, and heat, often long before alarms or catastrophic failure occur. This page explains which spindle designs are commonly used for steel milling, how wear typically presents,…

Read MoreOmlat D-Drive Spindles for Steel Milling

Direct-Drive Milling Spindles for Stiffness, Torque Density, and Thermal Control Omlat designs D-Drive (direct-drive) spindles for milling applications where steel cutting, stiffness, and torque consistency are more critical than belt isolation or ultra-high speed. Unlike belt-driven spindles, D-Drive spindles integrate the motor directly into the spindle assembly. This eliminates belts and pulleys, allowing for more…

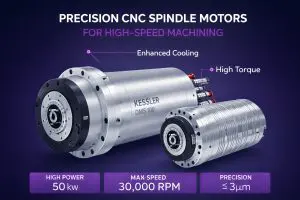

Read MoreKessler DMS 100 Spindle Repair: Milling Stability Under Sustained Load

The Kessler DMS 100 is engineered for demanding milling applications where rigidity, thermal mass, and load capacity are critical to maintaining accuracy. When internal conditions begin to change, performance rarely drops off suddenly. Instead, users notice gradual shifts—milling accuracy drifting during longer or heavier cutting cycles, finish degrading under sustained load, or a shrinking stable…

Read More