Uncategorized

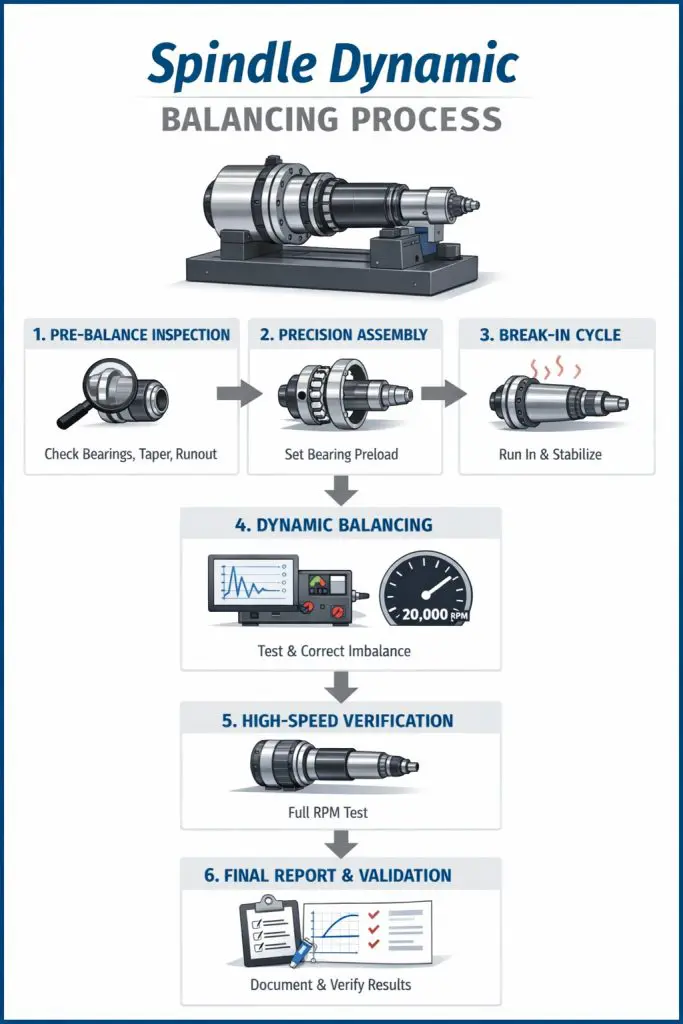

Spindle Dynamic Balancing Process

Dynamic balancing is one of the most critical—and often overlooked—steps in professional spindle repair. Even minor imbalance in a high-speed spindle can cause vibration, heat buildup, premature bearing failure, and poor surface finishes. A properly balanced spindle runs smoother, lasts longer, and delivers consistent machining accuracy. Below is an overview of how dynamic spindle balancing…

Read MoreCommon Spindle Myths That Cost Shops Money

CNC spindles are among the most expensive and critical components on a machine tool—yet they’re also one of the most misunderstood. Over the years, several persistent myths have led shops to delay repairs, ignore warning signs, or spend far more than necessary. Let’s break down the most common spindle myths—and explain what they really cost…

Read MoreSigns Your Spindle Needs Repair

A failing spindle rarely goes from “perfect” to “destroyed” overnight. In most cases, warning signs appear weeks—or even months—before catastrophic failure. Unfortunately, those early indicators are often ignored in the rush of daily production. Catching spindle problems early can mean the difference between a planned repair and an unplanned shutdown, scrapped parts, and a six-figure…

Read MorePrecision Spindle Repair Services

Spindle Repair Services: Restore Precision, Reduce Downtime, and Extend Machine Life In today’s precision manufacturing environment, spindle repair plays a critical role in maintaining productivity, accuracy, and equipment longevity. Because the spindle directly controls speed, accuracy, and surface finish, even minor spindle issues can quickly lead to scrap, downtime, and lost revenue. Therefore, manufacturers must…

Read More