How Spindle Contamination Leads to Bearing Failure

A Step-by-Step Look Inside CNC Spindle Damage

CNC spindle failure rarely happens all at once. In most cases, damage begins with microscopic contamination and progresses gradually until vibration, heat, and bearing failure become impossible to ignore. Understanding this progression helps operators identify problems early and avoid costly downtime.

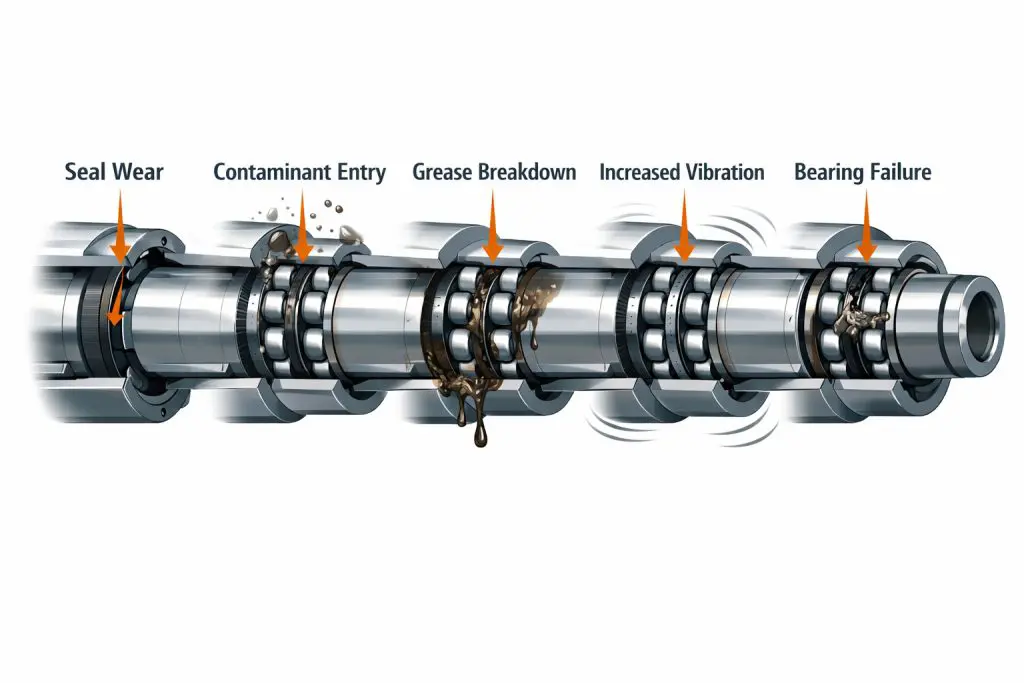

This diagram illustrates the five most common stages of spindle contamination and bearing failure.

Stage 1: Seal Wear and Initial Breakdown

Spindle seals are designed to reduce contamination, not eliminate it completely. Over time, seals wear due to heat, shaft movement, vibration, and abrasive particles. As wear increases, micro-gaps form between the seal and rotating shaft.

At this stage:

- The spindle may still sound normal

- Cut quality appears acceptable

- Damage remains invisible during routine inspections

However, once seal integrity degrades, the contamination process has already begun.

Stage 2: Contaminant Entry

As the spindle operates, pressure changes caused by heating, cooling, and rotation draw in fine particles such as:

- Dust and grinding debris

- Coolant mist and moisture

- Oil vapor and airborne contaminants

These particles migrate past worn seals and settle inside the spindle housing. Because contaminants are microscopic, they often go unnoticed during daily operation.

Stage 3: Grease Breakdown and Lubrication Failure

Once contaminants reach the bearing zone, they begin breaking down bearing grease. Coolant and moisture reduce lubrication effectiveness, while fine debris acts as an abrasive.

As lubrication degrades:

- Bearing friction increases

- Heat builds rapidly

- Bearing preload begins to change

At this point, spindle life shortens dramatically—even if the machine continues running.

Stage 4: Vibration and Thermal Instability

With damaged lubrication and worn bearing surfaces, the spindle loses stability. Vibration levels increase, thermal growth becomes unpredictable, and cutting forces fluctuate.

Common symptoms include:

- Chatter during finishing passes

- Reduced surface finish quality

- Shortened tool life

- Excessive heat at the spindle nose

Ignoring these warning signs allows damage to accelerate.

Stage 5: Bearing Failure and Spindle Shutdown

Eventually, bearing damage reaches a critical point. Preload collapses, vibration spikes, and temperatures exceed safe limits. At this stage, catastrophic bearing failure becomes likely.

Consequences often include:

- Emergency machine shutdown

- Damage to spindle housings or shafts

- Extended downtime

- Higher repair or replacement costs

Early intervention could have prevented this outcome.

Why Understanding Failure Progression Matters

Recognizing the early stages of spindle contamination allows manufacturers to:

- Schedule repairs before catastrophic failure

- Reduce total repair costs

- Avoid secondary damage to housings and shafts

- Maintain consistent machining accuracy

At Atlanta Precision Spindles, our repair process addresses every stage of contamination-related failure—not just the final symptoms.

How Atlanta Precision Spindles Prevents Repeat Failures

Professional spindle repair requires more than replacing bearings. Long-term reliability depends on eliminating contamination and restoring precision.

Our process includes:

- Ultrasonic cleaning of all internal components

- Inspection and restoration of seal interfaces and journals

- Clean-room spindle assembly

- Precision bearing preload and alignment

- Dynamic balancing and thermal testing

By addressing contamination at its source, we help ensure repaired spindles perform reliably in real production environments.

Take Action Before Failure Occurs

If your spindle shows early signs of vibration, heat, or surface finish issues, contamination may already be present.

Contact Atlanta Precision Spindles for a professional spindle evaluation and prevent minor contamination from becoming a major failure.