Kessler C 40 Spindle Repair: Precision Milling When Stability Starts to Shift

The Kessler C 40 is engineered for high-speed precision milling applications where tool interface stability, thermal control, and dynamic balance directly affect part quality. When internal conditions begin to change, performance rarely degrades suddenly. Instead, users notice subtle shifts—finish quality declining at higher RPM, accuracy changing as the spindle warms, or vibration appearing only in specific speed ranges—while the spindle itself continues to sound normal. These patterns often indicate internal bearing or balance-related changes rather than tooling or programming issues.

How the Kessler C 40 Is Used in Milling Applications

The C 40 is commonly installed in high-speed CNC milling centers performing:

- Finishing and semi-finishing operations

- Precision contouring and profiling

- Mold, die, medical, and aerospace machining

- Applications using HSK tooling, where repeatability and interface rigidity are critical

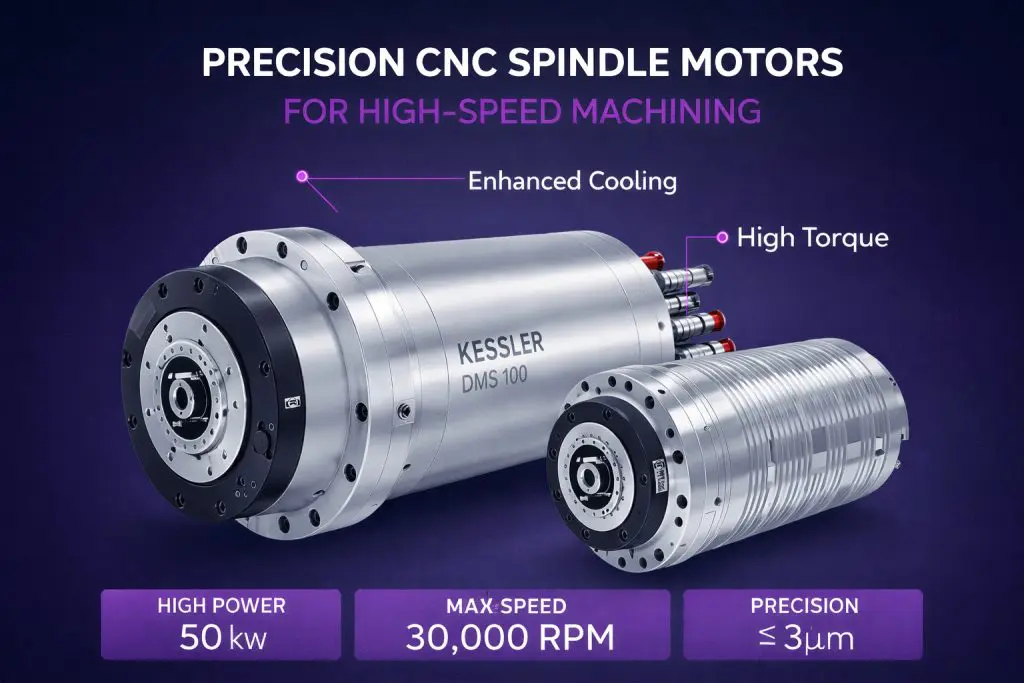

Unlike larger DMS spindles, the C 40 is optimized for speed and responsiveness, which means its performance is especially sensitive to bearing condition, balance, and thermal behavior.

Early Milling-Related Symptoms Seen in C 40 Spindles

Finish degradation at higher speeds

Users often report:

- Surface finish breaking down at upper RPM ranges

- Tool marks appearing inconsistently

- Improved results when RPM is reduced

Speed-specific vibration

As wear develops:

- Vibration appears only at certain speeds

- The spindle feels smooth outside those ranges

- Problems are difficult to reproduce at idle

These symptoms frequently appear before obvious noise or alarms.

What’s Typically Happening Inside the C 40 During Milling

Bearing wear and balance sensitivity

In high-speed milling:

- Even small bearing changes affect balance

- Thermal growth alters preload characteristics

- Tool interface stability becomes more sensitive

As bearings wear, the C 40 may remain quiet at low speed but become unstable as RPM increases.

Why Milling Issues Are Often Misdiagnosed

Initial troubleshooting often focuses on:

- Toolholders and pull studs

- Tool balance or runout

- CAM strategies and RPM selection

While these factors matter, recurring speed-dependent issues often trace back to internal spindle condition, not external setup alone.

Repair Options for Kessler C 40 Milling Spindles

Speed- and balance-focused spindle evaluation

A proper evaluation can:

- Identify bearing wear affecting balance

- Correlate vibration with RPM ranges

- Confirm whether rebuild is needed before damage escalates

Precision bearing rebuild and dynamic balancing

When wear is confirmed:

- Bearings are replaced to OEM-level specifications

- Preload is restored for high-speed operation

- Dynamic balance is verified across the operating range

The result is smoother operation, improved finish, and predictable behavior at speed.

Repair vs Replacement — A Common Decision Point

Because C 40 spindles are often used in high-value precision work, running through early symptoms can:

- Accelerate bearing damage

- Increase scrap or rework

- Expand repair scope later

In many cases, early repair restores performance at a fraction of replacement cost.

Manufacturer-Recommended Maintenance for Kessler Milling Spindles

According to Kessler documentation and service guidance, maintaining high-speed milling performance depends on practices that protect bearings and balance integrity.

Manufacturer guidance generally emphasizes:

- Proper warm-up before high-speed milling

- Avoiding shock loads during tool engagement

- Monitoring vibration and finish trends

- Maintaining clean cooling and lubrication systems

- Investigating speed-related issues early

Users should always consult official Kessler documentation specific to their spindle model and configuration for detailed guidance.

Preventative Practices That Help C 40 Spindles Last Longer

To extend service life in high-speed milling:

- Track finish and vibration relative to RPM

- Avoid operating continuously in unstable speed bands

- Address balance-related changes early

In high-speed milling, small internal changes show up quickly.

Illustrations are representative and used for educational purposes; actual spindle configurations may vary.