Why Wait Until Failure?

The Hidden Cost of Running a CNC Spindle to the Breaking Point

In many shops, spindle repair only happens after failure. The machine alarms, production stops, and the spindle gets pulled in an emergency. While this approach may feel unavoidable, it is also one of the most expensive ways to manage CNC spindle performance.

At Atlanta Precision Spindles, we regularly see spindles that could have been repaired weeks—or even months—earlier at a fraction of the cost. The question is simple: why wait until failure?

Spindle Failure Rarely Happens Without Warning

CNC spindles almost always show signs of distress before catastrophic failure. These warning signs are easy to overlook during daily production, but they are rarely subtle inside the spindle.

Common early indicators include:

- Increased vibration or noise

- Gradual loss of surface finish quality

- Rising spindle temperatures

- Shortened tool life

- Inconsistent machining results

These symptoms indicate internal wear, contamination, or bearing degradation. Left unaddressed, they compound quickly.

The Real Cost of Waiting Until Failure

Running a spindle until it fails often creates secondary damage that dramatically increases repair cost and downtime.

When failure occurs:

- Bearings overheat and disintegrate

- Shafts and housings can suffer scoring or distortion

- Preload collapses and balance is lost

- Repairs become more complex and time-consuming

In contrast, early intervention typically limits damage to bearings and wear components.

Waiting doesn’t save money — it multiplies cost.

Failure Turns Planned Maintenance Into an Emergency

Emergency spindle repair affects more than just the spindle itself.

It often leads to:

- Unplanned production downtime

- Missed delivery deadlines

- Expedited shipping costs

- Rush decisions with limited options

Planned spindle service allows shops to:

- Schedule downtime

- Control costs

- Avoid collateral machine damage

- Maintain consistent production schedules

Proactive repair puts control back in your hands.

Early Repair Preserves Precision and Machine Accuracy

As bearings wear and contamination spreads, spindle accuracy degrades long before failure. This degradation directly impacts:

- Tolerance control

- Surface finish

- Tool life

- Scrap and rework rates

By addressing spindle issues early, manufacturers preserve machining accuracy and protect downstream processes.

At Atlanta Precision Spindles, we focus on restoring precision before failure compromises performance.

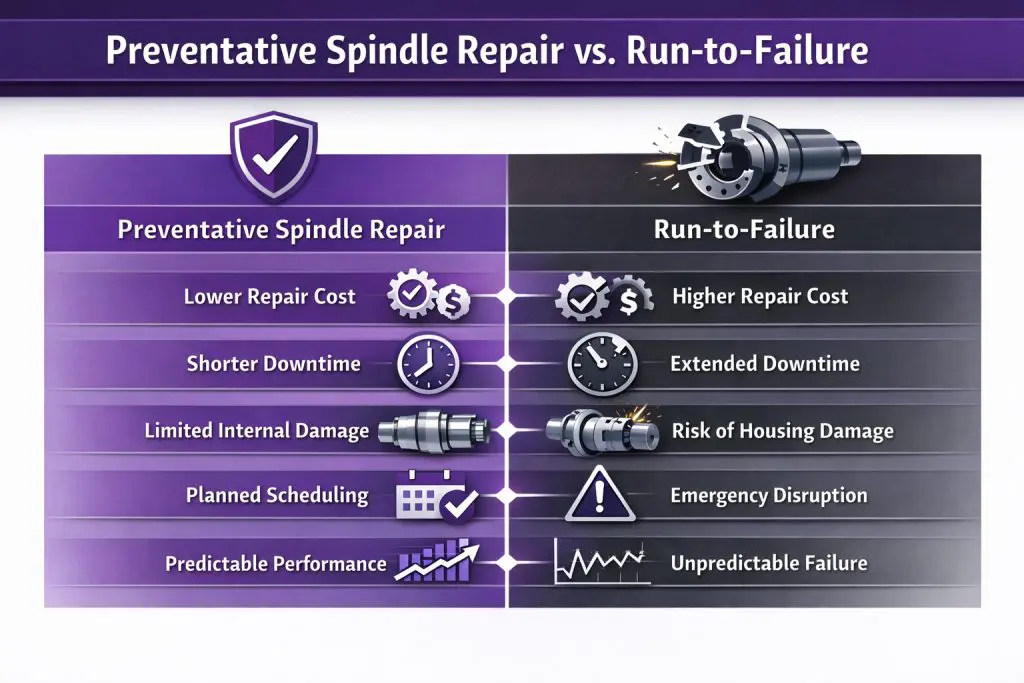

Preventative Spindle Repair vs Run-to-Failure

The difference isn’t theoretical — it shows up in every repair we see.

How Atlanta Precision Spindles Helps You Stay Ahead of Failure

Our approach focuses on identifying problems early and repairing spindles before damage escalates.

We provide:

- Diagnostic evaluation of vibration, heat, and runout

- Detailed inspection of bearings, journals, and seals

- Clean-room spindle assembly

- Precision balancing and thermal testing

- Documentation to support maintenance planning

This process helps customers transition from reactive repair to proactive spindle management.

When Should You Act?

If your spindle shows any of the following, it’s time to act:

- Noticeable vibration increase

- Surface finish changes

- Rising operating temperatures

- Tool life decline without explanation

Addressing these signs early can prevent catastrophic failure and reduce total cost of ownership.

Stop Waiting for Failure

CNC spindle failure is not inevitable — but the consequences of ignoring early warning signs are.

Why wait until failure when early repair costs less, takes less time, and protects machine accuracy?

CTA (End of Article):

Take control before failure occurs. Contact Atlanta Precision Spindles to schedule a spindle evaluation today.